#Data logger solutions

Explore tagged Tumblr posts

Text

Testo Data Loggers are advanced monitoring devices designed to record critical parameters such as temperature, humidity, and CO2 levels across diverse applications. Whether dealing with extreme temperature conditions or ambient environments, these devices ensure accurate and reliable data collection. Ideal for industries like food, pharmaceuticals, and logistics, Testo Data Loggers help maintain compliance with regulatory standards, ensuring optimal storage and transport conditions for sensitive goods.

#testo data logger#testo dataloggers#Data logger solutions#Wireless data loggers#humidity data loggers#Industrial data logging systems#data loggers#data loggers UAE#temperature data loggers

0 notes

Text

Keysight 34972A Lxi Data Acquisition Logger Switch Unit My41217227 - Auto2mation

The Keysight 34972A LXI Data Acquisition Logger Switch Unit MY41217227 from Auto2mation is a reliable, high-performance data logging and measurement solution. It features a built-in 6½ digit digital multimeter, 3-slot mainframe, and supports up to 120 channels for accurate data collection. Designed with LXI compliance, it allows easy network connectivity for remote monitoring and control. Ideal for both industrial and lab environments, this compact unit simplifies testing and data logging tasks. With its user-friendly interface and powerful capabilities, the 34972A ensures fast setup, precise measurements, and dependable performance for various test automation needs.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#Keysight#Data Acquisition#Logger Switch Unit#Switch

0 notes

Text

WiFi Dashboard for Solar Off-Grid Power Plants

This WiFi interface and Data Logger software are used mainly for Solar Off-Grid Power plants This contains wifi connection information, parameter dials, operational status, energy consumption status and fault status of the Unit History option allows the user to access the data history of a particular unit by searching the modem id. Upto 100 entries can be viewed in a single page. Every five minutes the data will be logged in the history and refreshed Data Config option allows the user to configure the data in the dashboard of a particular unit WiFi credential is to connect the unit to the desired wifi network. This can be achieved by entering Modem id, Network name and Password Switch option in the side panel allows the remote operation of the unit. The whole unit or only the charging can be turned ON/OFF from the dashboard by operating the respective ON and OFF tabs User manual option provides the instructions to configure modem to the wifi network and also use the website dashboard

Don’t forget to LIKE, COMMENT, and SUBSCRIBE for more renewable energy solutions and solar projects!

Enquire Now: 9035024760 or [email protected]

Follow our LinkedIn page: https://www.linkedin.com/company/53510028/admin/dashboard/

Follow our Facebook page: https://www.facebook.com/UniparEnergySystemsPvtLtd

Follow our Instagram: https://www.instagram.com/uniparenergysystemspvtltd/

Subscribe our YouTube channel: https://www.youtube.com/watch?v=3hchIw7CFjw

Visit our website: https://unipar.in/

#off grid solar system#off grid solar power systems#off grid solar electric system#grid off solar system#off grid inverter#off grid solar inverter#inverter solar off grid#grid off inverter#inverter grid off#pv inverter off grid#off grid solar#grid solar system

2 notes

·

View notes

Text

Quality First: How Invimeds Ensures Top-notch Quality in Generic Medicines Supply

In the current pharmaceutical landscape, there is a growing demand for generic medicines driven by factors such as affordability and accessibility. Invimeds, as a top generic medicine distributor in this sector, prioritizes the delivery of high-quality products to healthcare providers and patients globally. Quality assurance is central to our operations, from sourcing to distribution, ensuring the safety and efficacy of every medication we supply.

Sourcing From Trusted Partner

Our dedication to quality is the meticulous selection of suppliers. We exclusively partner with esteemed manufacturers and suppliers who uphold Good Manufacturing Practices (GMP) and rigorous quality control standards. Through collaborations with WHO GDP-certified manufacturers and suppliers, Invimeds guarantees that each product meets the most stringent global quality criteria.

Stringent Quality Control Measures:

Quality assurance is paramount at every stage of Invimeds' supply chain. Upon receiving products, thorough quality checks are conducted to verify authenticity, potency, and purity. We strictly adhere to regulatory standards set by global health authorities like the FDA and EMA, ensuring all products meet the highest safety and efficacy benchmarks.

This includes maintaining optimal storage and transportation conditions to preserve product integrity throughout the supply chain. Our specialized support team is dedicated to providing tailored solutions for patients and healthcare professionals, backed by our commitment to compliance, stringent quality control, and ethical practices.

Transparent Documents:

As a distributor of generic drugs, we prioritize your health and offer transparent services. We provide comprehensive documentation, including COA, Batch Report, COO, COPP, and more, for your review, fostering trust and confidence in our products and processes.

At Invimeds Health, we offer a new standard in pharmaceutical distribution, prioritizing efficient storage and secure handling of essential drugs. Our facilities feature advanced temperature and security controls, ensuring medication integrity in ambient, refrigerated, and sub-zero environments. From inventory management to distribution, we leverage advanced data loggers for precise supply chain management.

#pharmaceutical distributors#generic medicines#generic medicine distributor#supply of generic medicine

2 notes

·

View notes

Text

Rotary Torque Sensors: Enhancing Rotational Force Measurement with Star EMBSYS Solutions

Rotary torque sensors are critical components used to measure the rotational force (torque) applied on a rotating system, such as motors, gearboxes, or turbines. These sensors are essential in performance testing, quality control, and process monitoring across industries like automotive, aerospace, robotics, and manufacturing. Among the innovative providers in this space, Star EMBSYS offers high-performance, customizable rotary torque sensor systems that integrate advanced embedded technology for unmatched precision and reliability.

A rotary torque sensor measures torque by detecting the strain (twisting) on a rotating shaft. Typically based on strain gauge or magnetoelastic principles, these sensors output a signal proportional to the applied torque. Unlike static torque sensors, rotary torque sensors are designed to operate on rotating shafts, often using slip rings, wireless telemetry, or rotary transformers to transmit data.

Star EMBSYS brings its embedded systems expertise into torque sensing by offering intelligent rotary torque sensor solutions. These systems are equipped with real-time data acquisition, signal conditioning, and digital communication interfaces, making them ideal for dynamic and high-speed applications. Their sensors support both analog (voltage/current) and digital (UART, SPI, I2C, CAN) outputs, ensuring seamless integration with control systems, data loggers, and monitoring software.

One of the core strengths of Star EMBSYS is its ability to deliver customized sensor solutions tailored to the client’s mechanical and electrical requirements. Whether it's a high-precision lab-grade application or a rugged industrial setting, Star EMBSYS designs torque sensors with features like temperature compensation, vibration resistance, and long-term stability. Their embedded firmware ensures accurate real-time monitoring with minimal latency, critical for applications like EV motor testing or robotic joint torque feedback.

Additionally, Star EMBSYS offers user-friendly calibration and diagnostic tools, allowing engineers to maintain accuracy and system health over time. Their rotary torque sensors can be combined with wireless telemetry for remote monitoring, a vital feature for testing in mobile or rotating systems where cabling is impractical.

In conclusion, rotary torque sensors are essential for understanding and optimizing mechanical performance. Star EMBSYS stands out by delivering not just sensors, but smart embedded torque measurement solutions that empower engineers with real-time, high-fidelity data. With a commitment to innovation and customization, Star EMBSYS is a trusted partner for precision torque sensing in today’s demanding engineering applications.

Visit:- https://www.starembsys.com/rotary-torque-sensor.html

0 notes

Text

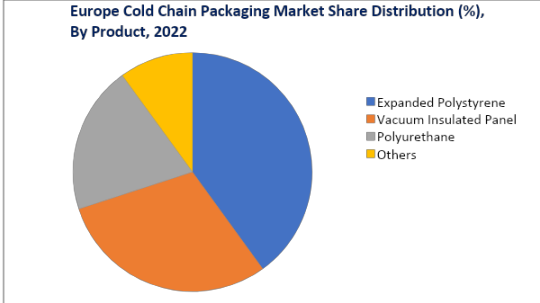

Future-Proofing Cold Chain Packaging in Europe with Circular Economy

The Europe Cold Chain Packaging Market is entering a period of robust expansion, projected to grow at a CAGR of 11.7%, reaching approximately USD 16.9 billion by 2030. This growth is attributed to a convergence of regulatory pressure, sustainability goals, rising pharmaceutical exports, and increased demand for perishable food transportation across the continent.

Germany, France, the UK, and Spain are leading the regional growth, supported by infrastructure development and increasing public-private investment in cold logistics. Cold chain packaging plays a critical role in ensuring the integrity and safety of temperature-sensitive products during storage and transport.

To Get Sample Report : https://www.datamintelligence.com/download-sample/europe-cold-chain-packaging-market

Key Market Drivers

Pharmaceutical Sector Expansion Pharmaceuticals represent a major growth vertical. Rising vaccine distribution, temperature-sensitive biologics, and strict EU Good Distribution Practices are elevating packaging standards. Companies are increasingly adopting passive and active cooling systems, particularly in vaccine supply chains.

Stringent EU Regulations The European Union has introduced policies that mandate traceability, safety, and reduced environmental impact in packaging systems. These directives have accelerated innovation in recyclable and biodegradable packaging materials, while also demanding enhanced thermal insulation and monitoring capabilities.

Consumer Preference for Fresh & Healthy Products Consumers in Europe are increasingly inclined toward fresh, organic, and minimally processed food. This shift necessitates robust cold chain solutions from farm to shelf, increasing demand for efficient, safe, and eco-friendly packaging systems.

Technology Integration in Packaging IoT-enabled sensors, GPS tracking, and data loggers are becoming standard. These technologies ensure real-time temperature monitoring and geolocation tracking, reducing spoilage rates and improving regulatory compliance across the cold chain.

Sustainability and Circular Economy Trends The shift toward reusable and recyclable cold packaging is gaining momentum. Companies are exploring paper-based insulation, biodegradable foams, and reusable containers to meet EU Green Deal objectives and reduce plastic usage.

Growth Opportunities

Smart Packaging Solutions: Real-time analytics, AI-based tracking systems, and blockchain integration present investment opportunities in intelligent logistics.

Green Materials R&D: Development of plant-based insulation and compostable foams will help meet the growing demand for eco-conscious alternatives.

Public-Private Partnerships: Investment in rural cold chain infrastructure, especially in Eastern and Southern Europe, is key to reducing spoilage and increasing market penetration.

Reusable Packaging Systems: Adoption of reusable temperature-controlled packaging formats can reduce costs over time while aligning with sustainability mandates.

Regional Trends

Germany remains a dominant force, driven by its strong pharmaceutical manufacturing base and sophisticated logistics infrastructure.

UK recently saw over USD 160 million invested in a new cold storage facility capable of handling more than 100,000 pallets.

Spain is seeing growth in seafood trade and exports, increasing demand for marine-grade cold chain packaging.

France and the Netherlands are also investing in smart cold logistics with strong governmental and private sector support.

Global Market Comparison

While Europe leads with a significant portion of the global cold chain packaging market, rapid developments in Asia-Pacific are noteworthy. Japan’s cold chain packaging market reached USD 879.9 million in 2023 and is projected to grow at a CAGR of 13.6%, reaching over USD 2.14 billion by 2030. Paperboard packaging is the fastest-growing segment in Japan.

In the United States, regulatory and technological upgrades are being implemented, especially in seafood and pharmaceutical logistics. The national focus on supply chain resilience and climate-conscious packaging systems is creating new growth avenues.

Latest Industry Developments

United States: The U.S. National Seafood Strategy promotes cold chain investment in seafood transportation. Innovative companies are rolling out reusable packaging systems capable of maintaining thermal stability over extended periods, significantly reducing carbon emissions and packaging waste.

Japan: Driven by the demand for sustainability and temperature-sensitive pharmaceutical logistics, Japan is rapidly expanding its cold chain infrastructure. The rise of paper-based and recyclable insulation materials is being widely supported by regulatory initiatives and consumer preference.

Strategic Outlook

The Europe Cold Chain Packaging Market is strategically positioned to benefit from a combination of technological innovation, stricter environmental regulations, and booming pharmaceutical and food industries. Companies that prioritize smart packaging, sustainability, and collaboration across the supply chain are likely to lead the next wave of growth.

Stakeholders are encouraged to:

Invest in R&D for next-generation biodegradable materials

Integrate IoT and real-time monitoring into packaging systems

Strengthen cross-border logistics partnerships for regulatory alignment

Explore reusable and refillable packaging as part of a circular economy

0 notes

Text

Global Electrical Resistance Probes Market Evolution: Sustainability and Digital Monitoring Trends

MARKET INSIGHTS

The global Electrical Resistance Probes Market was valued at US$ 293 million in 2024 and is projected to reach US$ 456 million by 2032, at a CAGR of 5.7% during the forecast period 2025-2032. The U.S. accounted for the largest regional market share at approximately 32% in 2024, while China is expected to witness the fastest growth with an estimated CAGR of 6.8% through 2032.

Electrical resistance probes are precision instruments designed to measure corrosion rates in metallic structures by detecting changes in electrical resistance caused by material loss. These devices play a critical role in corrosion monitoring across industries, employing either straight or curved configurations to suit different installation requirements. The probes function by comparing the resistance of a measuring element (exposed to corrosive environments) with a protected reference element.

The market growth is primarily driven by stringent industrial safety regulations, particularly in oil & gas infrastructure where corrosion monitoring prevents catastrophic failures. Water treatment applications are gaining traction due to increasing investments in municipal infrastructure, accounting for nearly 28% of total probe deployments in 2024. Key manufacturers like Emerson and Cosasco are expanding their portfolios with IoT-enabled probes, reflecting the industry’s shift toward predictive maintenance solutions. Recent advancements include wireless data transmission capabilities and improved sensor materials that extend probe lifespan in harsh environments.

MARKET DYNAMICS

MARKET DRIVERS

Growing Industrial Corrosion Monitoring Needs to Accelerate Market Expansion

The global Electrical Resistance Probes market is experiencing robust growth driven by increasing industrial demand for corrosion monitoring solutions. With corrosion costing industries approximately 3-4% of GDP annually in developed nations, facilities are prioritizing asset integrity management. Electrical Resistance Probes provide real-time metal loss measurements, enabling predictive maintenance strategies. The oil & gas sector alone accounts for over 40% of probe deployments due to harsh operating environments where corrosion can compromise safety and profitability. Latest advancements include wireless probe systems that reduce installation costs by up to 30% while improving data accessibility.

Stringent Regulatory Standards Boosting Adoption Across Critical Industries

Government regulations mandating corrosion prevention measures are significantly propelling market growth. Industries such as chemical processing, power generation, and water treatment are mandated to implement corrosion monitoring systems to comply with safety and environmental standards. The water treatment segment is projected to grow at 6.8% CAGR through 2032 as municipalities upgrade aging infrastructure. Recent regulatory updates now require documented corrosion prevention plans in high-risk sectors, creating sustained demand for reliable monitoring technologies like Electrical Resistance Probes.

Additionally, technological advancements in probe design are enhancing market appeal:

➤ Leading manufacturers have introduced probes with 0.1μm resolution for early-stage corrosion detection, a significant improvement over traditional 1μm sensitivity thresholds.

Furthermore, the integration of IoT capabilities allows for centralized corrosion monitoring across multiple assets, driving operational efficiencies in large-scale industrial facilities.

MARKET RESTRAINTS

High Initial Investment Costs Limiting SME Adoption

While Electrical Resistance Probes offer compelling advantages, their market penetration faces obstacles from substantial capital requirements. Comprehensive corrosion monitoring systems including probes, data loggers, and software typically require investments ranging from $15,000-$50,000 per installation site. This creates significant barriers for small and medium enterprises, particularly in developing markets where cost sensitivity is high. Many facilities continue to rely on traditional inspection methods despite their limitations because of these upfront costs.

Additional Market Constraints

Technical Complexity in Interpretation The data generated by Electrical Resistance Probes requires specialized interpretation skills that many plant operators lack. Without proper training, facilities may underutilize these systems or make incorrect maintenance decisions based on probe readings.

Environmental Limitations Extreme operating conditions including temperatures above 150°C or highly abrasive environments can reduce probe lifespan and measurement accuracy, restricting applications in certain industrial settings.

MARKET CHALLENGES

Competition from Alternative Monitoring Technologies Intensifying Market Pressures

The Electrical Resistance Probes market faces growing competition from emerging corrosion monitoring technologies. Ultrasonic thickness gauges, while requiring manual operation, offer lower per-measurement costs and have improved significantly in accuracy. Linear Polarization Resistance (LPR) probes are gaining traction in water systems due to their ability to measure corrosion rate rather than cumulative loss. This competitive landscape is forcing probe manufacturers to accelerate innovation cycles while maintaining price competitiveness.

Workforce Skill Gaps The industry faces a critical shortage of corrosion technicians qualified to install and maintain monitoring systems. With an estimated 15-20% of the current workforce approaching retirement, companies are struggling to recruit and train new personnel, potentially slowing market growth.

Data Integration Complexities Integrating probe data with existing asset management systems remains challenging for many operators. The lack of standardization across data formats creates additional hurdles for comprehensive corrosion management programs.

MARKET OPPORTUNITIES

Expansion in Renewable Energy Sector Presents New Growth Frontiers

The rapid growth of renewable energy infrastructure creates substantial opportunities for Electrical Resistance Probes. Offshore wind farms face aggressive corrosion conditions, with monitoring requirements expanding as installations move into deeper waters. The global offshore wind capacity is projected to grow eightfold by 2030, creating a parallel demand for robust corrosion monitoring solutions. Probe manufacturers are developing specialized marine-grade products to capitalize on this emerging market segment.

Smart Factory Initiatives Driving Demand for Connected Monitoring Solutions

Industry 4.0 adoption is accelerating the need for intelligent corrosion monitoring systems. Modern Electrical Resistance Probes with wireless connectivity and predictive analytics capabilities align perfectly with digital transformation initiatives. Leading manufacturers are partnering with industrial IoT platforms to offer integrated solutions, with the smart factory market projected to exceed $200 billion by 2026. This convergence of corrosion monitoring with digital technologies represents a significant growth vector for the sector.

Additionally, emerging markets present untapped potential:

➤ Asia-Pacific infrastructure development projects are driving 35% of global steel consumption, creating corresponding demand for corrosion protection systems across construction and transportation sectors.

ELECTRICAL RESISTANCE PROBES MARKET TRENDS

Growing Demand for Corrosion Monitoring in Critical Industries Drives Market Expansion

The global Electrical Resistance Probes (ERP) market is experiencing steady growth, primarily driven by increasing demand for corrosion monitoring across oil & gas, water treatment, and infrastructure sectors. With corrosion costing industries an estimated $2.5 trillion annually worldwide, representing 3-4% of GDP in industrialized nations, ERPs have become essential preventive maintenance tools. These probes monitor metal loss by measuring resistance changes in thin sensing elements exposed to corrosive environments, offering continuous condition assessment without process interruption. The market is projected to grow at a CAGR of 5.8% from 2024 to 2032, with the oil & gas sector accounting for over 40% of current demand due to stringent safety regulations and asset preservation requirements.

Other Notable Trends

Technological Advancements in Probe Design and Connectivity

Recent years have seen significant innovation in ERP technology, particularly in wireless connectivity and data integration capabilities. Modern probes now feature IoT-enabled sensors that transmit real-time corrosion data to centralized monitoring systems, reducing manual inspection requirements by up to 60%. Manufacturers are also developing hybrid probes that combine electrical resistance measurement with other techniques like linear polarization resistance for more comprehensive corrosion assessment. High-temperature resistant variants capable of operating in environments exceeding 400°C are gaining traction in refinery applications, addressing a key limitation of traditional probes.

Increasing Emphasis on Predictive Maintenance Strategies

The shift from reactive to predictive maintenance approaches across process industries continues to propel ERP adoption. When integrated with advanced analytics platforms, resistance probes enable corrosion rate trend analysis and remaining life predictions with over 85% accuracy. This implementation has demonstrated potential to reduce unplanned downtime by 30-50% in offshore drilling operations while cutting maintenance costs by approximately 20%. The water treatment sector represents the fastest-growing application segment at projected 7.2% CAGR, driven by aging infrastructure replacement programs and stricter water quality regulations that necessitate comprehensive pipeline integrity monitoring.

COMPETITIVE LANDSCAPE

Key Industry Players

Market Leaders Focus on Corrosion Monitoring Innovations to Maintain Competitive Edge

The global electrical resistance probes market features a moderately consolidated structure, with established corrosion monitoring specialists competing alongside diversified industrial conglomerates. Emerson Electric Co. emerged as a dominant force in 2024, leveraging its comprehensive Emerson Rosemount corrosion measurement portfolio and extensive service network across critical oil & gas infrastructure projects worldwide.

Cosasco and Metal Samples Company maintained strong market positions through their specialized corrosion monitoring solutions, particularly in hazardous environments. These companies benefited from increasing emphasis on asset integrity management in petrochemical facilities, where electrical resistance probes are increasingly deployed for real-time corrosion rate measurements.

Strategic developments have intensified competition, with several players expanding their technological capabilities through recent acquisitions. Axess Corrosion strengthened its offshore monitoring solutions through sensor innovation, while Europcorr enhanced its electrochemical testing capabilities with new probe designs for high-temperature applications.

Emerging participants like BORNA Electronics are disrupting traditional markets through cost-optimized probe configurations, particularly in water treatment applications across Asia-Pacific. Meanwhile, established players continue investing in wireless probe technologies and cloud-based corrosion data platforms to differentiate their offerings.

List of Key Electrical Resistance Probes Companies

Emerson Electric Co. (U.S.)

Cosasco (U.S.)

Axess Corrosion Technology AS (Norway)

Caproco International Inc. (Canada)

Metal Samples Company (U.S.)

Europcorr Technologies (France)

BORNA Electronics Ltd. (UK)

Segment Analysis:

By Type

Straight Electrical Resistance Probes Dominate the Market Due to Their Versatility in Industrial Applications

The market is segmented based on type into:

Straight

Curved

By Application

Oil and Gas Sector Leads Due to High Demand for Corrosion Monitoring in Pipelines and Storage Tanks

The market is segmented based on application into:

Oil and Gas

Water Treatment

Others

By End-user Industry

Process Industries Maintain Significant Adoption for Asset Integrity Management

The market is segmented based on end-user industry into:

Petrochemical

Power Generation

Chemical Processing

Manufacturing

By Measurement Technology

Four-point Probe Technology Gains Traction for Precise Corrosion Rate Measurement

The market is segmented based on measurement technology into:

Two-point Probe

Four-point Probe

Linear Polarization Resistance

Regional Analysis: Electrical Resistance Probes Market

North America The North American market for Electrical Resistance Probes is driven by stringent industrial safety regulations and the presence of established oil & gas infrastructure. The region is witnessing increased adoption of corrosion monitoring technologies, particularly in the U.S. and Canada, where aging pipelines and chemical plants necessitate advanced monitoring solutions. Key players like Emerson and Metal Samples Company dominate the market with their technologically advanced probe designs. The U.S. remains the largest consumer due to its extensive industrial base, while Canada shows steady growth due to its oil sands operations. However, market expansion faces challenges from competition with alternative corrosion monitoring methods such as ultrasonic testing.

Europe Europe’s Electrical Resistance Probes market benefits from strict EU directives on industrial safety and environmental protection. The region emphasizes high-precision corrosion monitoring, particularly in the offshore oil & gas sector and water treatment plants. Germany and the UK lead in adoption rates due to their strong manufacturing sectors and focus on preventive maintenance. Latest developments include the integration of wireless probe systems for real-time data collection. While Western Europe maintains steady demand, Eastern European markets show growth potential due to infrastructure modernization. The market faces constraints from budget limitations in some industries and competition from lower-cost alternatives.

Asia-Pacific This rapidly growing region is propelled by industrial expansion in China, India, and Southeast Asia. China’s massive oil & gas sector and water treatment initiatives generate the highest demand for electrical resistance probes in the region. India shows exceptional growth potential due to increasing investments in chemical processing plants and infrastructure development. Japanese manufacturers focus on high-precision probe technologies, while Southeast Asian markets prefer cost-effective solutions. Challenges include price sensitivity among smaller operators and inconsistent regulatory enforcement. Nevertheless, the region remains crucial for global market growth, with multiple projects in pipeline monitoring and industrial water treatment driving demand.

South America The South American market shows moderate growth, primarily supported by Brazil’s oil industry and Argentina’s chemical processing sector. While adoption rates are slower compared to other regions, increasing awareness about preventive maintenance is driving demand. Brazil’s pre-salt oil fields present significant opportunities for corrosion monitoring solutions. However, economic instability and currency fluctuations periodically affect market growth. The region shows preference for mid-range probe technologies and gradual adoption of advanced monitoring systems. Infrastructure challenges and limited technical expertise in some areas continue to restrain market expansion despite the clear need for corrosion monitoring solutions.

Middle East & Africa The GCC countries lead the Electrical Resistance Probes market in this region, driven by massive oil & gas operations and desalination plant requirements. Saudi Arabia and the UAE invest heavily in corrosion monitoring to protect critical infrastructure. Africa shows uneven adoption patterns, with South Africa and North African countries demonstrating more advanced usage compared to Sub-Saharan regions. Market growth faces obstacles from budget constraints in some African nations and preference for basic monitoring methods. Nonetheless, ongoing industrialization and infrastructure projects across the region indicate long-term market potential, particularly for integrated monitoring systems.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Electrical Resistance Probes markets, covering the forecast period 2024–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global Electrical Resistance Probes market was valued at USD XX million in 2024 and is projected to reach USD XX million by 2032.

Segmentation Analysis: Detailed breakdown by product type (Straight, Curved), application (Oil & Gas, Water Treatment, Others), and end-user industry to identify high-growth segments and investment opportunities.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa, with country-level analysis where relevant. The U.S. market size is estimated at USD XX million in 2024, while China is projected to reach USD XX million by 2032.

Competitive Landscape: Profiles of leading market participants including Emerson, Cosasco, Axess Corrosion, Caproco, Metal Samples Company, Europcorr, and BORNA Electronics, covering their product offerings, market share, and recent developments.

Technology Trends & Innovation: Assessment of emerging technologies, material advancements, and evolving industry standards in corrosion monitoring solutions.

Market Drivers & Restraints: Evaluation of factors driving market growth along with challenges, including regulatory requirements and industry-specific barriers.

Stakeholder Analysis: Strategic insights for manufacturers, suppliers, end-users, and investors regarding market opportunities and the competitive ecosystem.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/global-gaas-power-amplifier-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ambient-light-sensor-for-display-system.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/solar-obstruction-light-market-to-reach.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ac-dc-power-supply-converter-market-to.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/boost-charge-pump-ics-market-to-reach.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-motion-detector-sensor-market-to.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/x-ray-inspection-for-security-market-to.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-spatial-filters-market-to-reach.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-e-beam-liner-market-advancements.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-active-quartz-crystal-oscillator.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-ultrasonic-radar-market-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-ammeter-shunt-resistors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-wifi-and-bluetooth-rf-antenna.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-industrial-control-printed.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/global-scanning-transmission-electron.html

0 notes

Text

Revolutionizing Temperature Monitoring with IoT and DAQ Data Loggers

In an era where real-time data and remote monitoring define operational efficiency, industries dealing with temperature-sensitive products are rapidly shifting toward smarter, data-driven technologies. Whether it's food logistics, pharmaceutical storage, or scientific research, maintaining controlled environments is crucial. Enter the world of IoT data loggers, cold chain data loggers, and DAQ data acquisition systems—solutions that are transforming traditional monitoring into intelligent automation.

The Rise of IoT Data Logger Technology

The IoT data logger is at the forefront of this transformation. Unlike conventional loggers, IoT-enabled devices can wirelessly transmit temperature, humidity, pressure, and other environmental metrics in real time to cloud-based platforms. These systems eliminate the need for manual data retrieval and provide instant alerts if conditions deviate from pre-set parameters.

IoT data loggers are widely adopted in industries like cold storage, transportation, pharmaceuticals, and agriculture. The ability to access live environmental data through mobile apps or web dashboards enables businesses to act immediately, reducing the risk of product loss and improving overall accountability.

The Critical Role of Cold Chain Data Logger Devices

When dealing with temperature-sensitive goods such as vaccines, frozen foods, or laboratory samples, maintaining a consistent cold chain is vital. This is where a cold chain data logger becomes essential. These specialized loggers are engineered to monitor and record temperature and humidity during the transportation and storage of perishable goods.

Cold chain data loggers not only capture environmental changes but also generate detailed reports for regulatory compliance (such as FDA, WHO, or GDP standards). Many modern loggers offer USB plug-and-play access or wireless syncing capabilities, allowing for quick and easy data downloads.

These devices are used in:

Pharmaceutical shipments: Ensuring vaccine integrity during global distribution.

Food logistics: Tracking temperature consistency for dairy, seafood, or frozen items.

Clinical trials: Preserving the reliability of lab samples and biological agents.

Retail & warehousing: Ensuring compliance across storage facilities and outlets.

Understanding DAQ Data Acquisition Systems

DAQ (Data Acquisition) systems refer to the process of collecting and analyzing real-world physical signals—such as temperature, voltage, or pressure—and converting them into digital data that can be processed by a computer. In temperature monitoring systems, DAQ plays a critical role by enabling high-speed, high-accuracy data collection and analysis.

A DAQ data acquisition system, when integrated with a logger, enhances the monitoring process by allowing for real-time feedback loops, advanced analytics, and automated responses. For instance, in a pharmaceutical manufacturing plant, a DAQ-enabled system can immediately trigger alarms or activate cooling systems if temperature thresholds are crossed.

The synergy of DAQ technology with IoT data loggers and cold chain data loggers allows for scalable, modular systems that fit various applications—from a single warehouse to a multi-location global distribution network.

Benefits of Advanced Data Logging Systems

Real-Time Monitoring: Instant access to environmental data across geographies.

Regulatory Compliance: Generate automated audit-ready reports.

Loss Prevention: Minimize spoilage or damage by reacting to alerts in real-time.

Improved Efficiency: Reduce manual errors and labor costs through automation.

Data Transparency: Enable informed decision-making with continuous insights.

Conclusion

As industries become more reliant on precision and accountability, advanced tools like IoT data loggers, cold chain data loggers, and DAQ data acquisition systems are no longer optional—they’re essential. These technologies empower businesses to ensure product integrity, meet compliance standards, and gain real-time control over environmental conditions across the entire supply chain. By adopting smart monitoring solutions, companies are not just safeguarding their products—they’re building trust, efficiency, and long-term resilience.

0 notes

Text

Shop Testo: Your Destination for Premium Measuring and Monitoring Solutions

Looking for reliable and innovative measuring equipment? Visit Shop Testo, the ultimate hub for professional measuring devices. Catering to industries such as food safety, pharmaceuticals, HVAC, and more, Shop Testo offers a wide range of tools designed to ensure precision and compliance.

At Shop Testo, you’ll find the equipements that simplify complex tasks. Our selection of temperature monitoring devices includes advanced systems like WiFi-enabled loggers, cloud-based monitoring tools, and high-accuracy thermometers. These devices help to maintain optimal conditions for storage and production, making them essential for businesses that prioritize quality and safety.

For those seeking professional measuring devices, Shop Testo provides a diverse range of instruments tailored to various applications. From humidity meters and air velocity testers to CO2 monitors and data loggers, our devices are designed for precision, durability, and ease of use. Each product meets the highest industry standards, ensuring you have the right tools for your professional needs.

What sets Shop Testo apart is our commitment to customer satisfaction. With detailed product descriptions, user-friendly interfaces, and expert support, we make it easy for you to select the best tools for your operations. Plus, our fast and secure online shopping experience ensures you get the equipment you need, when you need it.

Whether you’re a food safety professional, an HVAC technician, or a laboratory specialist, Shop Testo is the ideal solution for you. Explore our wide range of professional measuring devices to optimize your workflow, enhance accuracy, and maintain compliance with industry regulations.

#Professional measuring devices#Testo measuring instruments#Environmental monitoring devices#Temperature monitoring devices#Humidity monitoring solutions#Food safety measuring tools#Data loggers for industrial use

0 notes

Text

Top Temperature Data Logger Manufacturers in India | Nimbus Technologies

Nimbus Technologies is one of the trusted temperature data logger manufacturers in India, offering reliable, made-in-India solutions for pharma, food, logistics & labs. With USB/cloud access, real-time alerts & custom options, our loggers ensure precise monitoring & compliance.

0 notes

Text

Applications of Temperature and Humidity Data Loggers in Environmental Monitoring

In today's fast changing world, Environmental monitoring has become a crucial part, and collecting accurate data is at its core. So, as indispensable tools, temperature and humidity data loggers have emerged. As we understand the importance of these tools, we offer an ultimate solution to achieve your environmental monitoring.

Temperature and humidity data logger or data recorders are the electric devices that are capable of measuring temperature and humidity data during any storage, transportation, and in many other industries.

Temperature data loggers

A temperature data logger is the electrically sensor devices that record accurate data over time in different temperatures. These devices are play a vital role in many industries. The most common and widely used application is environmental monitoring. In a particular area data loggers can record real time, precise temperatures so that industries can keep a close eye on the environment. iVision's temperature loggers keep track of data in real-time and make sure you can react quickly to any deviations, maintaining the quality of your products and reducing waste.

Humidity data loggers

Our humidity data loggers help you keep the right humidity levels so that delicate materials are safeguarded and to prevent moisture-related damage. With the help of the humidity data loggers from iVision, you can track on humidity patterns in a proper way, identify potential problems, and take preventative measures.

Environmental integration Monitoring

Our capability to integrate temperature and humidity data loggers into a complete environmental monitoring system sets us apart from the competition. This enables you to manage and keeps an eye on a number of variables at once, including CO2 levels and air quality. Our user-friendly interface offers configurable notifications, historical data analysis, and real-time insights to keep you informed and in control.

Conclusion

At ivision.com.co, your environmental monitoring initiatives will be seamless and dependable because to our dedication to quality and accuracy. Whether its precious artefacts, medications, or crops, you can rely on us to give you the tools you need to safeguard your assets. For more information on our complete environmental monitoring solutions, get in touch with us right now.

#Temperature and Humidity Data Logger#temperature solution specialists#temperature solutions UAE#Humidity#Temperature solution provider UAE#Data loggers#disposable loggers#warehouse monitoring system uae#temperature monitoring system#single-use loggers#multi-use datalogger#temperature loggers#UAE#ivision#invention vision

1 note

·

View note

Text

Integrating ARMxy SBC with InfluxDB for Time-Series Monitoring

In the world of Industrial IoT (IIoT), the ability to efficiently monitor, store, and analyze large volumes of time-stamped data is essential. From environmental sensors in smart factories to energy meters in power systems, time-series data forms the backbone of real-time insight and historical analysis.

InfluxDB, an open-source time-series database, is designed specifically for these use cases. Combined with the industrial-grade ARMxy Edge Gateway, it creates a robust edge solution for reliable data acquisition, storage, and visualization—all without depending on cloud availability.

🧠 Why InfluxDB on ARMxy?

InfluxDB is lightweight, high-performance, and optimized for time-series workloads. It supports powerful query languages, retention policies, and integrations with monitoring tools such as Grafana. When deployed directly on an ARMxy (RK3568J/RK3568B2) gateway, it becomes a local data engine with key advantages:

Minimal latency: Store and query data at the edge

Offline reliability: Operate without cloud or internet connection

Flexible integration: Compatible with Modbus, OPC UA, MQTT, and more

🏭 Real-World Use Case Example

Imagine a factory floor with multiple PLCs controlling machinery. Each PLC sends temperature, vibration, and power consumption data every few seconds. Instead of sending that data to a remote server, it can be ingested directly into InfluxDB running on the ARMxy device.

You can then use:

Telegraf for parsing and collecting metrics

Grafana for local visualization dashboards

Node-RED to add logic and alarms

The result? A self-contained edge monitoring system capable of showing trends, detecting anomalies, and buffering data even during connectivity drops.

🔗 Integration Workflow Overview

Install InfluxDB on ARMxy via Docker or native ARM64 package

Connect data sources: Modbus devices, MQTT brokers, etc.

Configure retention policies to manage local storage

Use Grafana (also installable on ARMxy) to build dashboards

(Optional) Forward selected metrics to cloud or central server for backup

✅ Benefits of Edge Time-Series Monitoring

Faster Insights: No need to wait for data to hit the cloud

Bandwidth Optimization: Only send essential data upstream

Improved System Resilience: Data remains accessible during downtime

Security & Compliance: Sensitive data can stay on-premises

🔚 Conclusion

Deploying InfluxDB on ARMxy Edge Gateways transforms traditional data loggers into intelligent local data hubs. With flexible integration options, support for real-time applications, and a compact industrial design, ARMxy with InfluxDB is a perfect fit for smart manufacturing, energy monitoring, and any IIoT scenario that demands fast, local decision-making.

Let the data stay close—and smart.

0 notes

Text

CryoStork® Series Of Dry Shippers

Introduction

If you’re looking for a reliable dry shipper for your laboratory or medical facility, the CryoStork® Series from Cryolab provides a secure and efficient solution for transporting biological samples under cryogenic conditions. Designed for IVF clinics, clinical trials, and research laboratories, these dry shippers use advanced absorbent material to maintain temperature stability and ensure safety throughout transit.

Versatile and Volume-Focused Design

The CryoStork Series is available in five different models—CryoStork V2, V3, V4, V6, and V10—each tailored to meet specific volume requirements. With storage capacities ranging from two to ten litres, these units are ideal for a variety of applications, including IVF sample transport, embryo shipping, and cryogenic handling of sperm or other biological materials. Regardless of your storage needs, CryoStork offers a dependable, purpose-built solution.

Reliable Temperature Stability

CryoStork Dry Shippers are engineered for outstanding thermal performance. Their LN₂ vapour-phase system maintains ultra-low temperatures while minimising the risk of spillage or contamination. Optional data loggers are available to provide real-time internal temperature monitoring, ensuring continuous visibility and traceability during transit. With superior insulation and impressive hold times, CryoStork dry shippers safeguard your sensitive materials from temperature fluctuations.

Engineered for Safety and Compliance

Built to last, each CryoStork unit comes with a three-year vacuum warranty and complies with UKCA and CE certifications. These dry shippers are also ISO standard-compliant, making them suitable for use in regulated medical environments such as hospitals, fertility centres, and IVF clinics. Every unit includes round sample canisters as standard. For additional protection during transportation, customers can opt for a robust aluminium-framed trolley case with custom internal foam cushioning to protect valuable samples against impact.

A Trusted Solution for Cryogenic Transport

CryoStork Dry Shippers are trusted across the healthcare and research sectors for their durability, performance, and compliance with international shipping regulations. Whether transporting frozen embryos, clinical specimens, or research samples, CryoStork delivers a safe, seamless, and dependable cryogenic transport experience.

Learn More

To find out more about the CryoStork Series or explore Cryolab’s full range of cryopreservation solutions, visit www.cryolab.co.uk. Let Cryolab help you meet your cryogenic transport needs with innovation, safety, and confidence.

0 notes

Text

What to Look for in Industrial Measurement Equipment for Manufacturing Facilities

In manufacturing, precision is everything. Whether you're producing electronics, automotive components, pharmaceuticals, or food packaging, accuracy in measurement directly impacts quality, safety, and regulatory compliance. That’s why investing in the right industrial measurement equipment is not only a smart decision—it’s a critical one.

But with so many options on the market, how do you choose the right tools for your facility?

At EpicRise Electronics, we help businesses across industries source high-performance tools and IT equipment, including measurement systems, scanners, and wholesale label printers. Here's what to look for when equipping your manufacturing facility with industrial measurement solutions.

1. Accuracy and Reliability

The foremost priority in any measurement equipment is accuracy. Whether you're measuring weight, temperature, humidity, voltage, or dimensional properties, even the smallest margin of error can lead to production defects, wasted materials, and safety issues.

Look for devices that meet or exceed ISO or NIST standards and are tested for industrial-grade precision. It’s also essential that the equipment performs consistently over time without needing frequent recalibration.

Tip: Opt for trusted manufacturers that offer certification or documentation on equipment accuracy. Brands partnered with EpicRise often come with reliability reports and compliance details.

2. Durability and Build Quality

Manufacturing environments are often harsh—subject to heat, moisture, dust, vibration, and continuous operation. Your measurement tools must be built for endurance.

When sourcing items such as laser measurement devices, multimeters, or pressure gauges, choose models specifically designed for industrial environments. Features to consider include:

Rugged casings (shock-proof, waterproof, dustproof)

High-quality connectors and cables

Resistance to chemicals or oil

Durability reduces downtime and repair costs—especially in 24/7 operations.

3. Integration with Existing Systems

Modern manufacturing facilities are increasingly automated and data-driven. Measurement devices should seamlessly integrate with your existing systems, whether that’s SCADA software, ERP platforms, or IoT networks.

Look for equipment with USB, Ethernet, or Bluetooth connectivity, and ensure it's compatible with your current software architecture. This allows real-time data collection and monitoring, improving decision-making and traceability.

Pro Tip: Integration also extends to your labeling and tracking tools. For instance, pairing a Zebra barcode scanner with automated weighing or inspection stations ensures that product IDs and measurement data flow smoothly across systems.

4. Ease of Use and Operator Training

Complex equipment that requires excessive training can slow down operations and increase the likelihood of user error. Choose tools that offer intuitive interfaces, clear displays, and simple calibration procedures.

Many leading brands also offer training resources, online support, and documentation. These are crucial when onboarding new team members or troubleshooting issues on the production floor.

At EpicRise, we prioritize stocking measurement tools with user-friendly design, backed by strong manufacturer support and documentation.

5. Scalability and Upgrade Potential

Your facility’s needs today might not be the same five years from now. The best industrial measurement systems are modular or scalable—allowing you to expand or upgrade without overhauling your entire process.

For example:

Multichannel data loggers can be expanded with additional sensors.

Barcode readers and scanners can be upgraded with advanced software.

Integrated systems can support added devices as your production grows.

When planning for growth, choose flexible solutions that evolve with your operations.

6. Data Logging and Traceability Features

In highly regulated industries—like food, medical devices, or aerospace manufacturing—data traceability is non-negotiable. Measurement tools should offer internal storage, cloud connectivity, or the ability to export logs securely.

This helps meet compliance standards (e.g., FDA, ISO 9001) and supports quality audits, troubleshooting, and continuous improvement initiatives.

Pairing your measurement devices with wholesale label printers also boosts traceability. With every reading, you can instantly generate barcode labels that reflect batch numbers, inspection dates, or critical data points.

7. Brand Reputation and Support

With industrial-grade tools, it pays to choose reputable brands with proven track records. These manufacturers typically offer:

Better warranties

Firmware updates

Technical support

Long-term availability of spare parts

One such example is Zebra Technologies, a leader in tracking and scanning tools. Their Zebra barcode scanner models are known for reliability in industrial environments, offering high-speed scanning, rugged durability, and seamless integration with other factory systems.

EpicRise is proud to offer Zebra products, along with measurement devices and peripherals from top global brands.

8. Cost Efficiency Through Wholesale Channels

Quality measurement equipment can be a major investment, especially if you’re outfitting an entire facility. Buying through a distributor like EpicRise Electronics means you gain access to wholesale pricing, faster shipping, and expert consultation.

Need to bundle tools with scanning devices, power supplies, or network equipment? We make procurement simple and affordable by offering:

Wholesale label printers

Bulk orders of barcode scanners and sensors

Compatible accessories and software

You don’t have to compromise quality for budget—EpicRise delivers both.

Final Thoughts

Investing in the right industrial measurement equipment pays dividends across your manufacturing operation—from better product quality and compliance to increased efficiency and cost savings. But success starts with sourcing smart.

When you work with EpicRise Electronics, you get more than just tools—you get a trusted partner in procurement. From Zebra barcode scanner systems to durable measurement devices and wholesale label printers, we supply the equipment that powers precision manufacturing.Need help choosing the right gear for your facility? Explore our full product range at EpicRiseElectronics.com or contact our support team for a custom quote today.

0 notes

Text

Torque Sensors: Enabling Smart Mechanical Systems – Engineered by Star EMBSYS

Torque Sensors: Enabling Smart Mechanical Systems – Engineered by Star EMBSYS

In today’s era of automation, robotics, and precision engineering, measuring torque—the rotational force applied to an object—is fundamental. From electric vehicles to industrial machinery, the ability to accurately monitor torque enables smarter control, better performance, and enhanced safety.

At Star EMBSYS, we specialize in developing and integrating torque sensor systems into embedded platforms for a wide range of industrial and research applications. Whether it's for real-time monitoring, automated testing, or predictive maintenance, torque sensing is at the heart of many high-performance systems.

What is a Torque Sensor?

A torque sensor, also known as a torque transducer or torque meter, is a device that measures the twisting force applied on a rotating or stationary shaft. The sensor converts this mechanical input into an electrical signal, which can then be read and processed by a controller, data logger, or embedded system.

Torque sensors come in two main types:

Rotary Torque Sensors – Measure torque in rotating systems.

Static (Reaction) Torque Sensors – Measure torque without shaft rotation.

How Torque Sensors Work

Most modern torque sensors operate based on:

Strain Gauge Technology: Detects minute changes in resistance as torque deforms a sensor element.

Magnetoelastic Sensing: Uses changes in magnetic properties under stress.

Optical or Capacitive Techniques: Employed in specialized high-precision applications.

At Star EMBSYS, we primarily use strain gauge-based sensors due to their balance of sensitivity, reliability, and cost-effectiveness.

Applications of Torque Sensors

Torque sensors are used in:

Industrial Automation – Monitoring load on motors, pumps, and gearboxes.

Automotive Systems – Engine and drivetrain testing, EV torque analysis.

Robotics – Force feedback in joints and actuators.

Test Benches – Real-time torque measurement in R&D labs.

Aerospace & Defense – Component testing under dynamic loads.

Medical Devices – Precision torque control in surgical tools.

Star EMBSYS provides embedded solutions that make torque data actionable—by offering precise real-time feedback, wireless transmission, and cloud-based analytics.

What Sets Star EMBSYS Apart

Custom-Tailored Sensor Integration: Torque range, accuracy, and interface customized to your needs.

Advanced Embedded System Design: Microcontroller- and FPGA-based systems with high-resolution ADCs.

Real-Time Data Processing: Filtering, calibration, and display via PC, mobile, or industrial HMIs.

IoT-Ready Solutions: For remote torque monitoring and predictive maintenance.

Whether you need a compact board-level integration or a complete torque testing setup, Star EMBSYS delivers reliable, scalable, and efficient solutions.

Case Example: Torque Monitoring in Electric Motor Assembly

In one recent project, Star EMBSYS engineered a torque sensing solution for an electric motor assembly line. Using high-precision strain gauge sensors connected to an embedded control unit, operators could monitor torque during bolt tightening in real time. The result? Improved assembly quality, reduced component failure, and full traceability of torque data—accessible from both local terminals and the cloud.

Conclusion

Torque sensors are critical components in today’s intelligent mechanical systems. With the right sensor and embedded integration, companies can gain deeper insights, improve control, and ensure operational safety.

At Star EMBSYS, we combine sensor expertise with embedded design to deliver robust, accurate, and application-specific torque measurement solutions.

Need torque sensing in your system? Get in touch with Star EMBSYS—your partner in smart mechanical measurement.

Visit:- https://www.starembsys.com/torque-sensor.html

0 notes

Text

Temperature Data Logger Market Growth Drivers Transforming Global Industry Dynamics Rapidly

The Temperature Data Logger Market is witnessing significant growth driven by several critical factors shaping its expansion globally. Temperature data loggers are essential devices that record temperature over time, ensuring safety, quality, and compliance in various sectors such as pharmaceuticals, food and beverage, healthcare, and logistics. Understanding the key drivers propelling this market helps businesses and investors capitalize on emerging opportunities and address evolving industry needs.

One of the primary drivers of the Temperature Data Logger Market is the increasing demand for reliable temperature monitoring solutions in the pharmaceutical and healthcare industries. Maintaining strict temperature control during the storage and transportation of vaccines, medicines, and biological samples is critical to preserve their efficacy and safety. With the surge in vaccine distribution globally, especially highlighted by the COVID-19 pandemic, the need for temperature data loggers has intensified. These devices help ensure that sensitive products remain within required temperature ranges throughout the supply chain, reducing spoilage risks and compliance violations.

Technological advancements are another vital driver fueling the market’s growth. Modern temperature data loggers are equipped with wireless connectivity, real-time monitoring, and cloud-based data management features, allowing users to track temperature variations remotely and receive instant alerts in case of anomalies. The integration of Internet of Things (IoT) technology has enhanced the efficiency and accuracy of these devices, making them more user-friendly and adaptable across diverse applications. Innovations such as compact designs, longer battery life, and multi-parameter sensing capabilities have broadened their usability, thereby increasing market penetration.

Strict government regulations and industry standards related to temperature control and monitoring have also accelerated the adoption of temperature data loggers. Regulatory bodies worldwide mandate precise temperature tracking in sectors like food processing, pharmaceuticals, and cold chain logistics to ensure consumer safety and product quality. Compliance with regulations such as the FDA’s Good Manufacturing Practices (GMP), WHO guidelines, and HACCP (Hazard Analysis and Critical Control Points) is driving businesses to invest in advanced temperature monitoring systems. These regulatory requirements create a steady demand for temperature data loggers, especially in regions with stringent quality control standards.

The growth of cold chain logistics is another significant market driver. With the rise in global trade of perishable goods, including fresh food, seafood, and temperature-sensitive pharmaceuticals, efficient cold chain management has become paramount. Temperature data loggers play a crucial role in monitoring environmental conditions during transportation and storage, reducing the risk of product degradation. Increasing consumer awareness about food safety and quality further supports the expansion of cold chain infrastructure, indirectly boosting the demand for temperature data logging solutions.

Furthermore, expanding end-use industries contribute to market growth. Apart from healthcare and food, sectors such as agriculture, chemical manufacturing, and environmental monitoring require precise temperature measurement to optimize operations and maintain product integrity. For example, in agriculture, monitoring soil and storage temperatures helps improve crop yields and reduce wastage. Similarly, in chemical industries, maintaining controlled temperature conditions is essential for safe processing and storage of volatile substances. The broadening application scope enhances the overall demand for temperature data loggers.

Cost-effectiveness and ease of use also act as drivers for widespread adoption. Many temperature data loggers are now designed to be plug-and-play devices that require minimal technical expertise, encouraging small and medium-sized enterprises to implement temperature monitoring solutions. Additionally, the availability of affordable models without compromising accuracy has made these devices accessible to a larger customer base. This democratization of temperature monitoring technology is expected to contribute substantially to market growth in emerging economies.

The rising trend of digitalization and Industry 4.0 initiatives across manufacturing and supply chain operations further supports the Temperature Data Logger Market. Organizations aiming to enhance transparency, traceability, and operational efficiency adopt advanced temperature monitoring tools integrated with data analytics platforms. The insights generated from temperature data help businesses make informed decisions, reduce wastage, and comply with safety standards. The synergy between digital transformation and temperature data logging presents a promising growth avenue.

Lastly, increasing awareness of sustainability and reduction of food and drug wastage is encouraging industries to implement efficient temperature control measures. Temperature data loggers provide actionable insights that help reduce losses caused by improper storage conditions, supporting eco-friendly practices and cost savings. As environmental concerns become a priority globally, this driver will play a more significant role in shaping market dynamics.

In summary, the Temperature Data Logger Market growth is propelled by multiple intertwined drivers: escalating demand for temperature-controlled logistics, technological innovations, regulatory compliance, expansion of end-use industries, and the digital transformation of supply chains. These factors collectively create a robust ecosystem supporting market expansion. Companies investing in research, product development, and strategic partnerships are well-positioned to leverage these growth drivers and capture emerging opportunities in this evolving market landscape.

0 notes